Researchers at University of Illinois at Urbana-Champaign, US have announced a performance breakthrough for their innovative 3D tin electrodes in lithium-ion batteries. The new technology stored several times the energy of currently used commercial high capacity anodes, as well as recording the highest power rating so far reported for such a high energy anode. The high surface area in this unique design means that batteries can be cheaper and lighter, with longer cycle life.

Researchers at University of Illinois at Urbana-Champaign, US have announced a performance breakthrough for their innovative 3D tin electrodes in lithium-ion batteries. The new technology stored several times the energy of currently used commercial high capacity anodes, as well as recording the highest power rating so far reported for such a high energy anode. The high surface area in this unique design means that batteries can be cheaper and lighter, with longer cycle life.

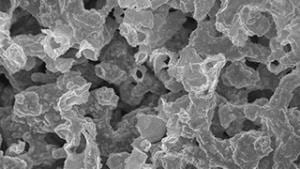

The new electrodes use a production-compatible electroplating process to coat a 20% tin layer onto a 3D nickel scaffold. This maximises the tin surface area while at the same time shortening the pathways for lithium ions to move through. The tin layer is protected from breaking up during charging using a carbon layer. Measured capacity by volume was 1,352 mAhcm-3, approaching ever closer the theoretical capacity for tin of 1,991 mAhcm-3. Commercial graphite anodes today have a practical capacity of ~550 mAhcm-3. Power performance of 750 mAhcm−3 at 10C was exceptional.

Working together with startup Xerion Battery Corp, the latest phase of the work was an important step towards industrial mass production and commercialisation. The team are optimising the technology, aiming to produce their first full cell prototype within a year.

University of Illinois paper, February 2019

University of Illinois research team webpage

Xerion Advanced Battery website

< Back to Lithium-ion Batteries

< Back to New Technologies