Scientists in China and Australia have shown how tin recovered from discarded electronics can be transformed into a powerful catalyst for clean hydrogen generation. Their work takes a major e-waste stream – multilayer ceramic capacitors (MLCCs) – and directly upcycles them into high-performance tin-containing catalysts.

Scientists in China and Australia have shown how tin recovered from discarded electronics can be transformed into a powerful catalyst for clean hydrogen generation. Their work takes a major e-waste stream – multilayer ceramic capacitors (MLCCs) – and directly upcycles them into high-performance tin-containing catalysts.

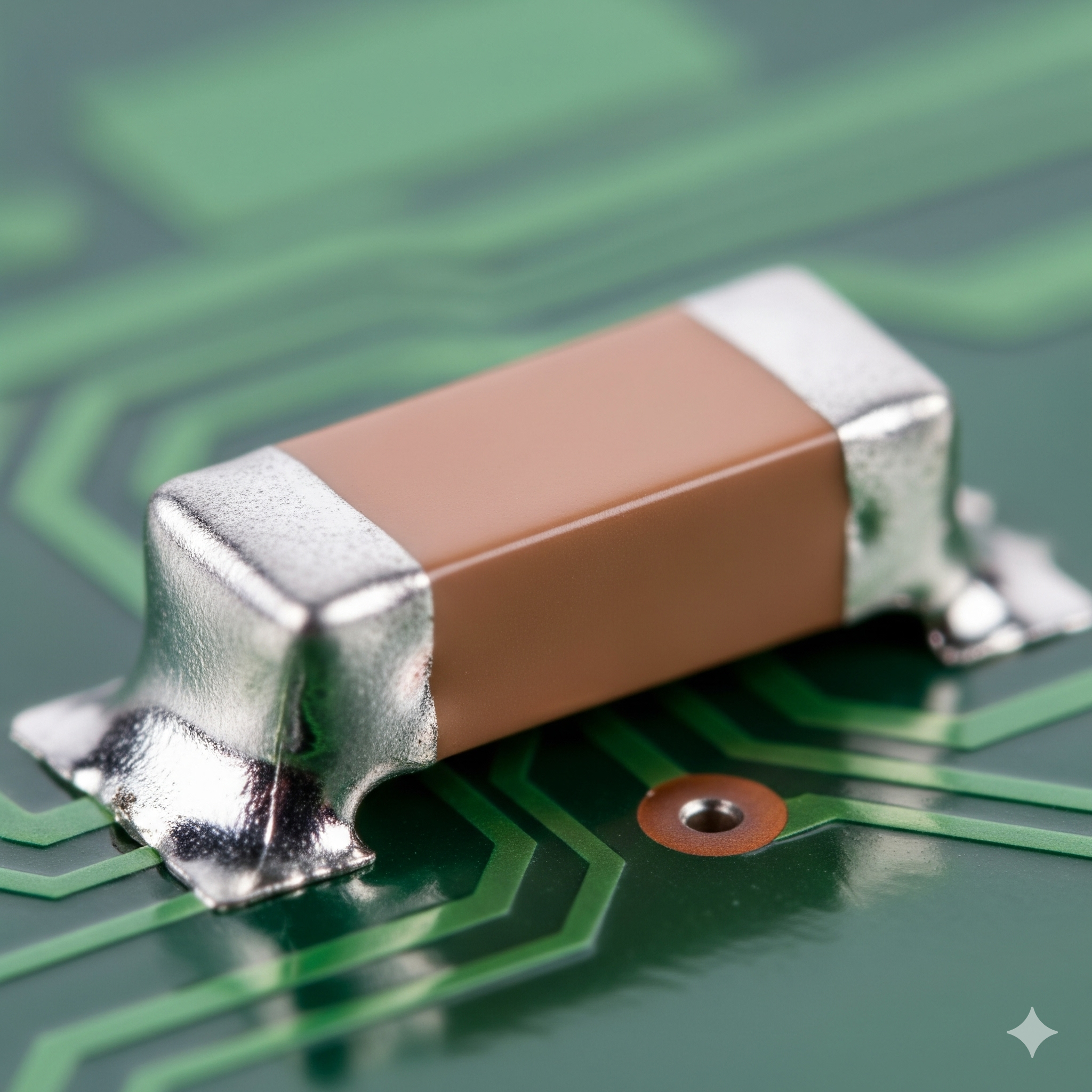

MLCCs, used in everyday devices from smartphones to televisions, are made of barium titanate (BaTiO₃, BTO) dielectrics with electrode layers that typically include tin, nickel, and copper. Instead of separating these metals through complex pre-treatments, the team applied a simple one-step ball milling process. This produced a magnetic Al-doped BTO/Ni-Sn-Cu composite catalyst where nanoscale BTO particles were coated with thin metallic Ni-Sn-Cu layers.

Tin plays a central role here: in alloy form with Ni and Cu, it enhances light absorption and charge separation, improving catalytic efficiency. In piezo-photocatalytic tests, the recycled material achieved hydrogen production rates of 345.8 μmol/g/h – more than four times higher than commercial BTO. Tin’s catalytic behaviour is well established, and in this system it helps unlock the synergy between the ceramic support and the metal alloy shell.

Equally important is the sustainability impact. Life cycle analysis showed the process cuts CO₂ emissions by 78% and reduces production costs by 70% compared to conventional catalyst synthesis – all while using e-waste directly as feedstock.

By converting tin-bearing MLCC waste into next-generation hydrogen catalysts, this research highlights tin’s importance in both the circular economy and renewable energy transition.

For more on emerging tin and e-waste technologies, visit Tin Valley, your hub for the future of tin.

< Back to New Technologies