Tin Recovery

Recovering tin from processes and products is key to reducing environmental impact and moving towards a circular economy. Tin recovery processes are diverse, and depend on the product from which tin is being recovered and the desired end product. In the past, tin recovery from waste has been overlooked due to the metal making up a very small proportion of consumer waste. As legislative and consumer pressure increases, tin recovery technologies from electronic and other waste is becoming both more innovative and economically viable.

For more information on tin recycling generally, see Tin Recycling.

Sustainable tin production using solar industry waste

Researchers from China have developed an innovative process to recycle tin from low-grade tin middlings, using silicon cutting waste (Si-CW) from the photovoltaic industry. This co-treatment strategy uses a difficult solar manufacturing byproduct to make tin...

Recycled tin from end-of-life solar tech

Researchers in Kunming, China have developed an environmentally friendly method to recover valuable metals, including tin, from photovoltaic (PV) ribbon waste, a rapidly growing component of end-of-life solar panels. Their two-step physical process separates copper,...

ITA visits Bioscope to explore tin recovery from e-waste

The International Tin Association’s technology team, Dr. Jeremy Pearce and Georgia Laurie, visited Bioscope at their Cambridge facility to learn more about the company’s innovative work recovering tin and other valuable metals from electronic waste. The visit reflects...

Unlocking tin through e-waste recycling

Electronic waste (e-waste) is the fastest-growing waste stream globally, with 62 billion kilograms generated in 2022 according to the Global E-Waste Monitor. Among the many valuable metals found in e-waste, tin plays a particularly crucial role. Tin is primarily used...

Aurubis to recover tin from new copper waste processing plant in Belgium

Aurubis’ new advanced sludge processing (ASPA) plant in Beerse, Belgium has officially opened its doors to start production.

The critical role of e-waste recycling

E-waste is an escalating global issue, driven by rapid technological advancements and high turnover of electronic devices. Due to tin’s use in a wide range of electronic devices and its resistance to corrosion, it also represents a growing feedstock for secondary tin...

Tin a target for Audi Environmental Foundation in new recycling research

The Audi Environmental Foundation (AEF), collaborating with the Freiberg University of Mining and Technology, Germany, is funding a research project focusing on a scalable recycling process. Named as "tweezer technology," this method selectively extracts strategic...

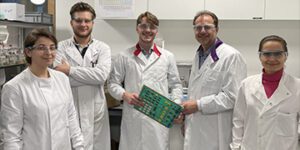

Tin from e-waste: ITA meets with bioleaching R&D team

More than a third of all tin is used in electronics every year. Although around of a third of all tin is recycled, more could be done to recover the metal from waste circuit boards. The Bioremediation Group, part of the Bioscience and Biotechnology Engineering...

Aurubis to invest in more efficient tin extraction

Aurubis has announced that it will build a state-of-the-art recycling plant at its Beerse site - previously Metallo - in Belgium. The new plant will process copper anode sludge using a hydrometallurgical process to rapidly extract a variety of metals including tin....

E-waste tin recovery success for EnviroLeach

Canadian e-waste recycler EnviroLeach have released new results showing that their environmentally friendly, cost-efficient process consistently recovers over four fifths of tin contained in circuit boards. The processed concentrate from crushed boards had an average...